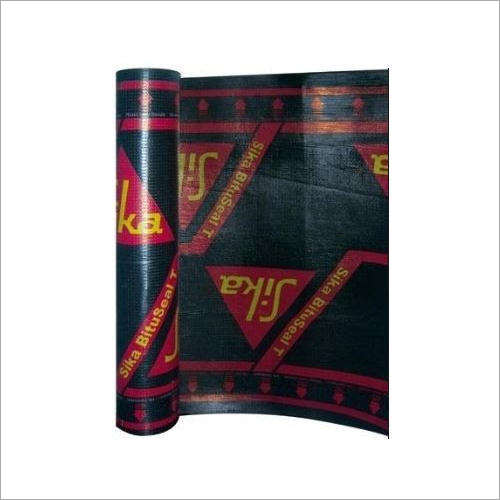

सिà¤à¤¾ बिà¤à¥à¤¸à¥à¤² à¤à¥ 140 à¤à¤¸à¤à¥ मà¥à¤®à¥à¤¬à¥à¤°à¥à¤¨ शà¥à¤

Price 3650 आईएनआर/ Roll

सिà¤à¤¾ बिà¤à¥à¤¸à¥à¤² à¤à¥ 140 à¤à¤¸à¤à¥ मà¥à¤®à¥à¤¬à¥à¤°à¥à¤¨ शà¥à¤ Specification

- घुलनशीलता

- Insoluble in water

- मेल्टिंग पॉइंट

- Softening point typically above 100°C

- प्रॉपर्टीज़

- Waterproofing, high flexibility, resistant to rot and mechanical damage

- दिखावट

- Black sheet with polyethylene surface finish

- सामग्रियां

- Bitumen, polyester reinforcement, polyethylene film

- पवित्रता

- Not specifically applicable

- प्रॉडक्ट टाइप

- सिका बिटसियल टी 140 एसजी झिल्ली शीट

- शेप

- आण्विक सूत्र

- Not applicable (Composite material)

- स्टोरेज

- कमरे का तापमान

- शेल्फ लाइफ

- 12 months in original, unopened packaging

- उपयोग

- Applied by torching or mechanical fixing to surfaces for waterproofing

- विषैला

- एप्लीकेशन

- इंडस्ट्रियल

- ग्रेड

- Industrial

- गंध

- स्ट्रक्चरल फॉर्मूला

- Not applicable (composite sheet material)

- एच एस कोड

- 680710

- भौतिक रूप

- घनत्व

- ग्राम प्रति घन सेंटीमीटर (g/cm3)

- Surface Finish

- Polyethylene film

- Tear Resistance

- High

- Installation Temperature

- Between +5°C and +35°C

- Width

- 1 m

- Length

- 10 m (roll)

- Waterproofing Performance

- Excellent - passes all standard industrial requirements

- Fire Classification

- EN 13501-5: Class E

- Reinforcement

- Polyester

- Thickness

- 4 mm

- Flexibility

- Remains flexible under low temperatures

- UV Resistance

- Good

About सिà¤à¤¾ बिà¤à¥à¤¸à¥à¤² à¤à¥ 140 à¤à¤¸à¤à¥ मà¥à¤®à¥à¤¬à¥à¤°à¥à¤¨ शà¥à¤

SPECIFICATION

| Ambient Temperature | +5deg C min to +50deg C max |

| Effective Thickness | 4mm |

| Elevated Temperatures | +120deg C from -10deg C |

| Elongation | 45% |

| External Fire Exposure | Class F roof t1-4 |

| Flow Resistance | 120deg C |

| Impact Resistance | 600 mm |

| Length | 10.00 m |

| Membrane Thickness | 4.00 mm |

| Reaction to Fire | Class F |

| Relative Humidity | 85 % |

| Sheer Resistance | 400 N / 50 mm |

| Substrate Moisture Content | 25 % |

| Substrate Temperature | +5deg C min to +65deg C max |

| Tear Strength | 160 N |

| Tensile strength Longitudinal | 700 N / 50mm |

| Tensile Strength Traversal | 600 N / 50mm |

| Unit Weight | 4.8 kg/m2 |

| Water Tightness | 60 kPa |

| Water Vapour Transmission | 0.2 g / 24 hours/m |

| Width | 1.00 m |

| Brand | Sika |

Superior Waterproofing and Durability

Sika Bituseal T 140 SG provides excellent resistance to water penetration, making it the go-to choice for industrial waterproofing projects. Its reinforced polyester layer ensures high mechanical strength while the polyethylene film protects against exposure and enhances durability. The membranes flexibility is retained at low temperatures, and its resistance to UV and mechanical damage assures long-lasting performance even under harsh conditions.

Simple Installation Process

This membrane sheet is designed for straightforward application, either by torching or mechanical fixing. Sika Bituseal T 140 SG can be installed at temperatures between +5C and +35C, ensuring adaptability to most Indian climates. Its 1-meter width and 10-meter roll format make it suitable for covering large surfaces efficiently, while the flexibility and tear resistance make handling and fitting easier for installers.

FAQs of Sika Bituseal T 140 SG Membrane Sheet:

Q: How is Sika Bituseal T 140 SG Membrane Sheet applied in waterproofing projects?

A: Sika Bituseal T 140 SG Membrane Sheet is typically applied using torch-on techniques, where heat is used to bond the sheet to the prepared substrate, or by mechanical fixing methods. Ensure the surface is clean and dry before application for optimal adhesion and performance.Q: What are the main benefits of using Sika Bituseal T 140 SG for industrial waterproofing?

A: The main benefits include excellent waterproofing properties, high resistance to tearing, consistent flexibility even under low temperatures, and good UV protection. Additionally, its resistance to rot and mechanical damage prolongs the lifespan of protected structures.Q: When and where can this membrane sheet be installed effectively?

A: This membrane can be installed effectively at ambient temperatures between +5C and +35C, making it suitable for most weather conditions encountered in India. It is ideal for large-scale roofing and structural waterproofing in industrial environments.Q: What is the process for preparing surfaces before applying the membrane sheet?

A: Surfaces should be thoroughly cleaned and dried to remove dust, debris, and moisture. A primer may be recommended for certain surfaces to improve adhesion. Proper surface preparation ensures a strong bond and optimal waterproofing performance.Q: How durable is Sika Bituseal T 140 SG against physical and environmental factors?

A: This membrane sheet offers high tear resistance, good UV stability, and flexibility at low temperatures. The polyester reinforcement and polyethylene film surface enhance its durability, making it capable of withstanding heavy industrial use and environmental exposure.Q: What is the shelf life and storage recommendation for Sika Bituseal T 140 SG?

A: The membrane has a shelf life of 12 months when stored in its original, unopened packaging at room temperature. It should be kept in a dry environment away from direct sunlight and excessive heat to maintain its quality.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in निर्माण रसायन Category

हाउस वॉटरप्रूफिंग केमिकल्स

न्यूनतम आदेश मात्रा : 10

माप की इकाई : टुकड़ा/टुकड़ाs

मूल्य या मूल्य सीमा : आईएनआर

एप्लीकेशन : इंडस्ट्रियल

प्रॉडक्ट टाइप : हाउस वॉटरप्रूफिंग रसायन

स्टोरेज : कमरे का तापमान

क्रैक फिलर केमिकल सील

न्यूनतम आदेश मात्रा : 10

माप की इकाई : किलोग्राम/किलोग्राम

मूल्य या मूल्य सीमा : आईएनआर

एप्लीकेशन : इंडस्ट्रियल

प्रॉडक्ट टाइप : दरार भराव रासायनिक सील

स्टोरेज : कमरे का तापमान

नॉन वेवन जियोटेक्सटाइल ड्रेनेज बोर्ड

न्यूनतम आदेश मात्रा : 50

माप की इकाई : स्क्वायर फुट/स्क्वायर फुट

मूल्य या मूल्य सीमा : आईएनआर

एप्लीकेशन : इंडस्ट्रियल

प्रॉडक्ट टाइप : गैर बुना हुआ भूभागीय ड्रानाज बोर्ड

स्टोरेज : कमरे का तापमान

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें